-

-

Products

-

347 Stainless Steel Plate

Classification:

Product Description

347 Stainless Steel Plate Description

347 stainless steel is more durable than other stainless steel materials under high temperatures. This makes it very popular when working in high temperature environments. In high-temperature corrosive environments, 347 stainless steel maintains its strength and durability without embrittlement or fatigue. 347 stainless steel also has excellent corrosion resistance. Its ability to remain stable in corrosive environments with strong acids and bases such as chloride ions and sulfide ions makes it ideal for use in the chemical and petroleum industries. In addition, 347 stainless steel also has good processing properties. It can be processed into various shapes by various methods such as forging, quenching, annealing and cold working. Its high temperature durability, corrosion resistance and processability make it popular in industries such as chemical, petroleum, pharmaceutical and food processing.

Product Parameters

|

Product Name |

347 Stainless Steel Plate |

|

Type |

Plate |

|

Thickness |

0.3mm-200mm |

|

Length |

2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

|

Width |

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

|

Standard |

ASTM, AISI, JIS, GB, DIN, EN, etc. |

|

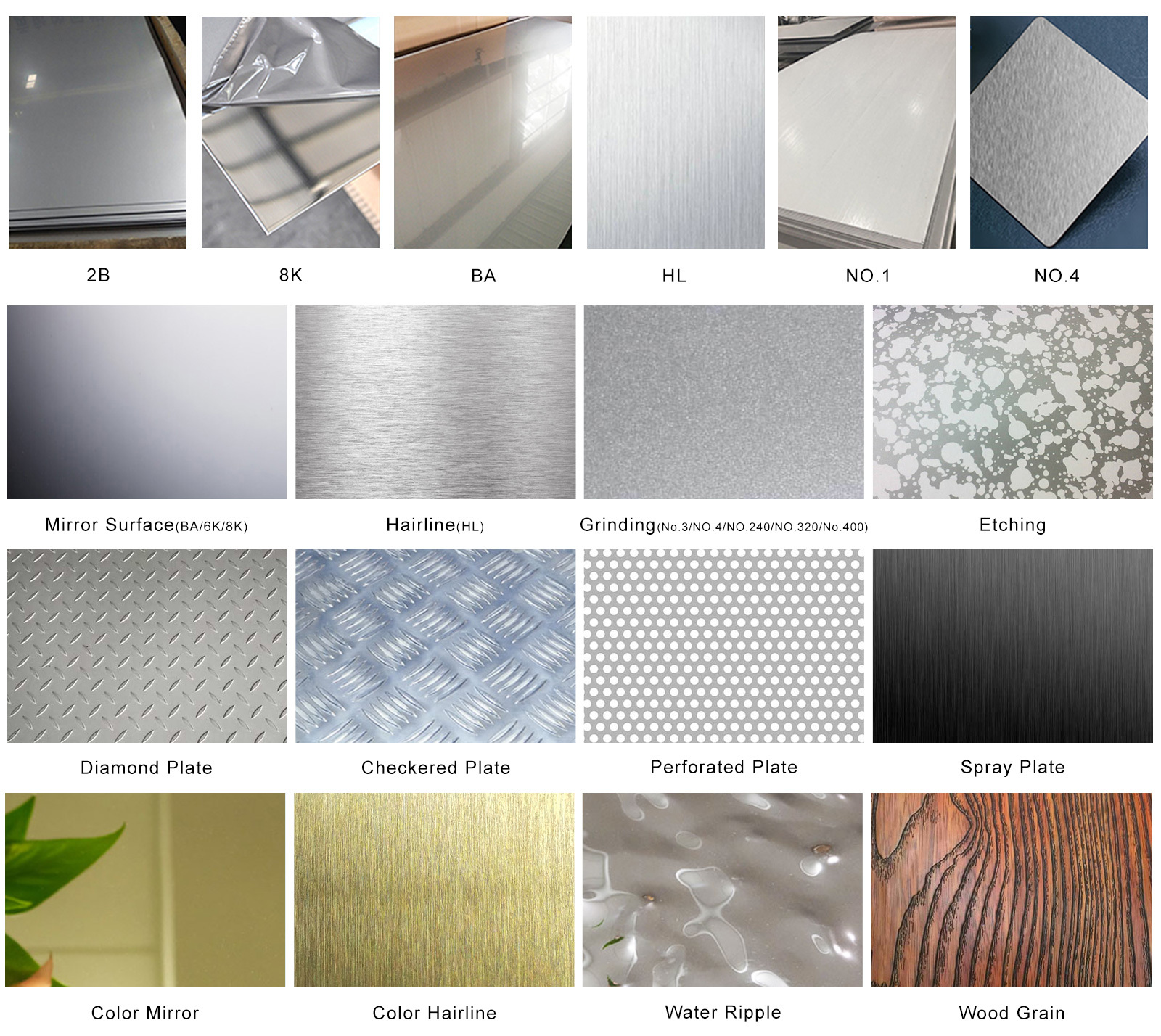

Surface |

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

|

Scope of Application |

Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

|

Certificate |

ISO, SGS, BV, etc. |

|

Production Technology |

Hot Rolling, Cold Rolling |

|

Edge Processing |

Edging, Trimming |

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.08 |

≤ 0.75 |

≤ 2.0 |

18.0~20.0 |

9.0~13.0 |

≤ 0.03 |

≤ 0.04 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥515 |

≥205 |

≥ 40 |

≤ 201HB;≤ 95HRB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.97 |

193 |

16.0 |

16.3 |

72 |

Surface Selection

Factory

Factory

Factory

Factory

Factory

Factory

Factory

Factory

Factory

Shipping

Shipping Photos

Shipping Photos

Shipping Photos

Shipping Photos

Faq

Are you a manufacturer?

Can we visit the factory?

How are the goods purchased shipped?

What is the delivery time?

Do we have access to samples? What are the costs?

How do we get a quote for a product?

Previous Page

Next Page

recommend products

Product inquiry

Filling in your phone and email information will help us to contact you in a timely manner and solve your problems as soon as possible.

Get a Free Consultancy

Get the latest information on the company's products

is an influential international and professional supplier of steel and non-ferrous metal raw materials.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Copyright © Shandong Shengde Metal Technology Co., LTD All Rights Reserved.