Categories

347 stainless steel is a high-temperature oxidation-resistant stainless steel material mainly composed of chromium, nickel and titanium. It is a stable material that can be used at high temperatures and can prevent corrosion and oxidation effectively.

305 stainless steel is a common austenitic stainless steel containing chromium, nickel, and manganese. Chromium can combine with oxygen to form a dense oxide film to protect materials from corrosion. Nickel can improve the material's heat resistance and toughness while reducing its magnetism. Manganese can increase the strength and hardness of materials.

403 stainless steel is a martensitic stainless steel with high chromium content and low carbon content. It is commonly used in applications requiring high strength and corrosion resistance.

409 stainless steel is a ferritic steel with good mechanical properties and high temperature corrosion resistance. It contains 11% chromium, which is the minimum amount required to form the passive surface film that makes stainless steel corrosion-resistant.

410 stainless steel is a commonly used martensitic stainless steel whose main components are iron, carbon, chromium and a small amount of other elements.

416 stainless steel coil has a chemical composition primarily including iron, chromium, nickel and other elements. 416 stainless steel has excellent corrosion resistance and mechanical properties because of this composition.

420 stainless steel is a high-carbon stainless steel, mainly consisting of chromium, carbon and molybdenum, with good corrosion resistance and strength.

430 stainless steel is a popular material for a variety of applications for its durability and corrosion resistance. However, welding 430 stainless steel can be challenging with its high chromium content.

439 stainless steel is a ferritic stainless steel with large amounts of chromium (approximately 18%) and low carbon content. This combination leads to its excellent corrosion resistance, especially in environments where chloride ions are present.

440C stainless steel is a high carbon martensitic stainless steel with high strength, moderate corrosion resistance, and good hardness and wear resistance. It is capable of attaining the highest strength, hardness and wear resistance of all the stainless alloys after heat treatment.

444 stainless steel is highly recognized for its excellent corrosion resistance and heat resistance. This stainless steel has a wide range of applications and can show stable performance in a variety of extreme environments.

405 stainless steel shows excellent corrosion resistance and good mechanical properties as an austenitic stainless steel material. It is widely used in numerous fields, especially in marine engineering, petrochemical industry, food processing and other fields.

304 stainless steel is a superior material with regard to corrosion resistance, heat resistance, low temperature strength and mechanical properties, as one of the most widely used types of stainless steel. In addition, it has exceptional hot-workability such as stamping and bending, without leaving heat treatment hardening phenomenon.

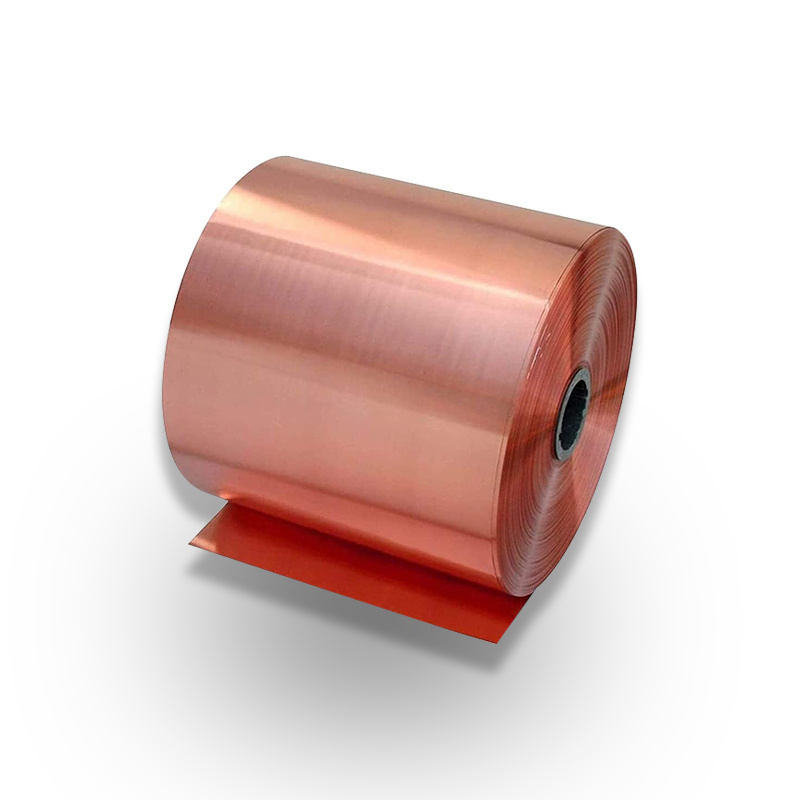

C12000 welding performance and cold bending performance is good, generally no "hydrogen disease" tendency, can be processed in the reducing atmosphere, use, but not in the oxidizing atmosphere of processing, use, mainly to pipe applications, can also be plate, belt or bar, line supply. Used as gasoline or gas transmission pipe, drain pipe, condenser pipe, mine pipe, condenser, evaporator, heat exchanger, train parts.

C12000 welding performance and cold bending performance is good, generally no "hydrogen disease" tendency, can be processed in the reducing atmosphere, use, but not in the oxidizing atmosphere of processing, use, mainly to pipe applications, can also be plate, belt or bar, line supply. Used as gasoline or gas transmission pipe, drain pipe, condenser pipe, mine pipe, condenser, evaporator, heat exchanger, train parts.

C12000 welding performance and cold bending performance is good, generally no "hydrogen disease" tendency, can be processed in the reducing atmosphere, use, but not in the oxidizing atmosphere of processing, use, mainly to pipe applications, can also be plate, belt or bar, line supply. Used as gasoline or gas transmission pipe, drain pipe, condenser pipe, mine pipe, condenser, evaporator, heat exchanger, train parts.

C12000 welding performance and cold bending performance is good, generally no "hydrogen disease" tendency, can be processed in the reducing atmosphere, use, but not in the oxidizing atmosphere of processing, use, mainly to pipe applications, can also be plate, belt or bar, line supply. Used as gasoline or gas transmission pipe, drain pipe, condenser pipe, mine pipe, condenser, evaporator, heat exchanger, train parts.

Docol 900M Martensitic Steels (MS)

Docol 900M martensitic steel helps improve collision resistance and provides reliable guarantees for lightweight design and cost-effective production in the automotive industry. Docol is one of the cold-rolled high-strength steels on the market and has become an ideal material for applications such as side impact beams, bumpers, and structural components in the automotive industry.